Rebar BO6: The Ultimate Guide To Reinforced Concrete Solutions

Rebar BO6 is a crucial component in modern construction, playing a pivotal role in reinforcing concrete structures. Whether you're a contractor, engineer, or simply someone interested in construction materials, understanding the importance of rebar BO6 is essential. This article will delve into everything you need to know about rebar BO6, from its specifications to its applications, ensuring you have a comprehensive understanding of this vital material.

Reinforced concrete is the backbone of countless construction projects worldwide. The strength and durability of concrete structures largely depend on the quality and type of rebar used. Among the various types of rebar available, rebar BO6 stands out due to its specific characteristics and applications. This guide will explore the technical aspects of rebar BO6, its benefits, and how it contributes to the longevity and safety of structures.

In this article, we will cover the key features of rebar BO6, its manufacturing process, and its role in construction. We'll also discuss how it compares to other types of rebar and provide practical insights for professionals in the construction industry. Whether you're planning a new project or simply expanding your knowledge, this guide will equip you with the necessary information to make informed decisions about rebar BO6.

Read also:How Old Is Jack Doherty Everything You Need To Know About The Rising Star

Table of Contents

- What is Rebar BO6?

- Specifications and Standards of Rebar BO6

- Manufacturing Process of Rebar BO6

- Applications of Rebar BO6 in Construction

- Advantages of Using Rebar BO6

- Comparison with Other Types of Rebar

- Installation Guidelines for Rebar BO6

- Maintenance and Care of Rebar BO6

- Environmental Impact of Rebar BO6

- Conclusion

What is Rebar BO6?

Rebar BO6 refers to a specific type of reinforcing steel bar that is widely used in construction projects. The "BO6" designation indicates the bar's size and grade, which are critical factors in determining its suitability for various applications. Rebar is typically made from carbon steel and is designed to enhance the tensile strength of concrete, which is inherently weak in tension.

The primary purpose of rebar BO6 is to provide structural integrity to concrete elements such as beams, columns, and slabs. By embedding rebar within concrete, engineers can ensure that the structure can withstand significant loads and stresses without cracking or failing. This makes rebar BO6 an indispensable material in the construction of bridges, buildings, highways, and other infrastructure projects.

Key Characteristics of Rebar BO6

- Size and Diameter: Rebar BO6 has a specific diameter that corresponds to its classification, ensuring it meets the structural requirements of a project.

- Grade: The "6" in BO6 indicates the grade of the rebar, which reflects its yield strength and other mechanical properties.

- Surface Texture: Rebar BO6 often features ribbed or deformed surfaces to improve bonding with concrete.

Specifications and Standards of Rebar BO6

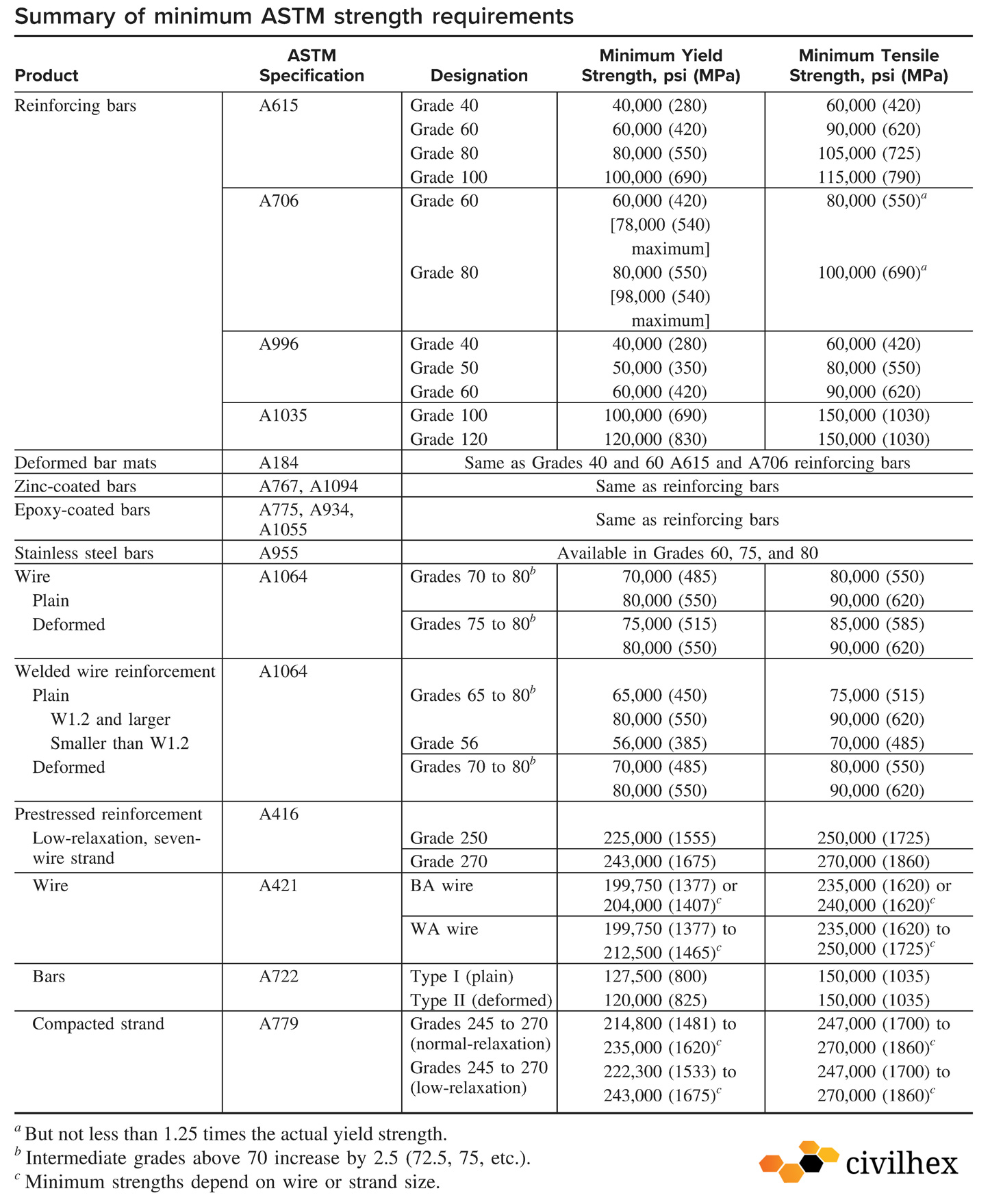

Rebar BO6 adheres to strict specifications and standards to ensure its quality and performance. These standards are established by regulatory bodies such as ASTM International and ISO, which set guidelines for the manufacturing, testing, and use of reinforcing steel bars.

One of the most widely recognized standards for rebar is ASTM A615, which specifies the requirements for deformed and plain carbon-steel bars for concrete reinforcement. Rebar BO6 must meet the mechanical properties outlined in this standard, including tensile strength, yield strength, and elongation.

Testing and Certification

- Tensile Testing: Ensures the rebar can withstand the required load without breaking.

- Bend Testing: Verifies the rebar's ability to bend without cracking.

- Chemical Composition Analysis: Confirms the material's compliance with carbon and alloy specifications.

Manufacturing Process of Rebar BO6

The production of rebar BO6 involves several stages, each designed to ensure the final product meets the required specifications. The process begins with the selection of raw materials, followed by melting, rolling, and finishing.

High-quality steel is melted in electric arc furnaces and then cast into billets. These billets are heated and passed through rolling mills to achieve the desired shape and size. The surface of the rebar is often deformed during this process to enhance its bonding capabilities with concrete.

Read also:Jeanluc Bilodeau A Rising Star In The Supernatural Universe

Quality Control Measures

- Inspection of Raw Materials: Ensures the steel meets the required chemical composition.

- In-Line Monitoring: Tracks the dimensions and surface quality during rolling.

- Final Testing: Conducts tensile, bend, and chemical tests on finished products.

Applications of Rebar BO6 in Construction

Rebar BO6 is utilized in a wide range of construction projects due to its versatility and strength. Its applications span various sectors, including residential, commercial, and infrastructure development.

One of the most common uses of rebar BO6 is in reinforced concrete structures such as foundations, beams, and columns. It is also widely employed in the construction of highways, bridges, and retaining walls, where its ability to withstand heavy loads is critical.

Examples of Projects Using Rebar BO6

- High-Rise Buildings: Provides the necessary reinforcement for vertical structures.

- Bridges: Ensures the structural integrity of spans and supports.

- Industrial Facilities: Reinforces floors and walls in heavy-duty environments.

Advantages of Using Rebar BO6

Rebar BO6 offers several advantages that make it a preferred choice for construction projects. Its unique properties contribute to the durability, safety, and cost-effectiveness of structures.

One of the primary benefits of rebar BO6 is its high tensile strength, which allows it to effectively reinforce concrete and prevent cracking. Additionally, its ribbed surface enhances bonding with concrete, ensuring a strong and stable structure.

Cost-Effectiveness and Sustainability

- Longevity: Reduces the need for frequent repairs and replacements.

- Recyclability: Made from recyclable materials, contributing to sustainability efforts.

- Energy Efficiency: Requires less energy to produce compared to other materials.

Comparison with Other Types of Rebar

While rebar BO6 is widely used, it is essential to understand how it compares to other types of rebar, such as epoxy-coated rebar or stainless steel rebar. Each type has its unique advantages and is suited for specific applications.

Epoxy-coated rebar, for example, is often used in environments where corrosion resistance is critical. Stainless steel rebar, on the other hand, offers superior durability but comes at a higher cost. Rebar BO6 strikes a balance between performance and affordability, making it a popular choice for many projects.

Key Differences

- Corrosion Resistance: Epoxy-coated and stainless steel rebar offer better resistance compared to BO6.

- Cost: Rebar BO6 is more cost-effective than stainless steel rebar.

- Strength: BO6 provides excellent tensile strength for its price point.

Installation Guidelines for Rebar BO6

Proper installation of rebar BO6 is crucial to ensure the structural integrity of a project. Contractors must follow specific guidelines to achieve the desired results and comply with safety standards.

Rebar BO6 should be carefully positioned within the concrete formwork to ensure even distribution and proper alignment. Spacers and supports are often used to maintain the correct placement and prevent displacement during the pouring of concrete.

Best Practices for Installation

- Pre-Planning: Design the reinforcement layout before installation.

- Use of Spacers: Maintain consistent concrete cover around the rebar.

- Quality Checks: Inspect the placement before pouring concrete.

Maintenance and Care of Rebar BO6

While rebar BO6 is designed to be durable, proper maintenance is essential to extend its lifespan and prevent issues such as corrosion. Regular inspections and timely repairs can help ensure the longevity of structures reinforced with rebar BO6.

Corrosion is one of the primary concerns when using rebar in concrete. Exposure to moisture and chemicals can lead to rusting, which weakens the structure. Applying protective coatings or using corrosion-resistant rebar can mitigate this risk.

Tips for Long-Term Care

- Regular Inspections: Identify and address signs of corrosion early.

- Protective Coatings: Use epoxy or other coatings to shield the rebar.

- Drainage Systems: Prevent water accumulation around the structure.

Environmental Impact of Rebar BO6

The production and use of rebar BO6 have environmental implications that must be considered. While it is a sustainable material in many ways, efforts should be made to minimize its ecological footprint.

One of the key environmental benefits of rebar BO6 is its recyclability. Steel is one of the most recycled materials globally, and rebar can be reused in new projects, reducing the demand for raw materials. However, the energy-intensive production process and potential for corrosion pose challenges that need to be addressed.

Sustainable Practices

- Recycling Programs: Encourage the reuse of steel in construction.

- Energy-Efficient Manufacturing: Adopt technologies to reduce energy consumption.

- Corrosion Prevention: Extend the lifespan of structures to reduce waste.

Conclusion

Rebar BO6 is an essential material in modern construction, offering unmatched strength, durability, and versatility. Its applications span a wide range of projects, from residential buildings to large-scale infrastructure, making it a cornerstone of the construction industry.

By understanding the specifications, manufacturing process, and advantages of rebar BO6, professionals can make informed decisions to ensure the success of their projects. Proper installation, maintenance, and consideration of environmental impacts are crucial to maximizing the benefits of this material.

We encourage you to share your thoughts or experiences with rebar BO6 in the comments below. If you found this guide helpful, please share it with others in the construction community. For more insights into construction materials and techniques, explore our other articles on this site.

Ellie Evelyn Smith Bio: A Comprehensive Guide To The Rising Star

Undress AI Free: Unveiling The Technology, Ethics, And Implications

Aagmaal Hot Web Series: A Comprehensive Guide To The Trending Show

Rebar RB6 Industrial Metal Supply

Rebar Sizes In Inches And Mm