Casting File: The Ultimate Guide To Understanding And Utilizing Casting Files In Manufacturing

Casting file is a critical component in modern manufacturing, particularly in industries like metalworking, automotive, and aerospace. It serves as a digital blueprint that contains essential data for creating molds, patterns, and casted components. If you’re looking to understand how casting files work, their importance, and how to leverage them effectively, you’ve come to the right place. This guide will walk you through everything you need to know about casting files, their role in production, and how they impact quality and efficiency.

In today’s fast-paced industrial landscape, precision and accuracy are non-negotiable. Casting files help streamline the manufacturing process by providing detailed instructions and specifications for producing high-quality casted parts. Whether you’re an engineer, a designer, or a business owner, mastering the use of casting files can significantly enhance your production capabilities. This article will explore the nuances of casting files, their applications, and how they align with industry standards.

By the end of this article, you’ll have a comprehensive understanding of casting files, their role in modern manufacturing, and actionable insights to implement in your operations. Let’s dive in and uncover the potential of casting files to revolutionize your workflow.

Read also:Jacquees Music Style A Deep Dive Into The Rampb Sensation

Table of Contents

- What is a Casting File?

- Importance of Casting Files in Manufacturing

- Types of Casting Files

- How Casting Files are Created

- Software for Creating and Managing Casting Files

- Applications of Casting Files in Various Industries

- Best Practices for Using Casting Files

- Common Challenges in Using Casting Files

- Future Trends in Casting File Technology

- Conclusion

What is a Casting File?

A casting file is a digital document or data set that contains all the necessary information to produce a casted component. This includes detailed specifications, dimensions, tolerances, material requirements, and other critical parameters. Casting files are typically created using computer-aided design (CAD) software and serve as a blueprint for manufacturers to follow during the casting process.

Casting files are used across various industries, from automotive to aerospace, to ensure consistency and precision in the production of complex parts. They are essential for both small-scale and large-scale manufacturing operations, as they provide a standardized way to communicate design intent and production requirements.

Key Components of a Casting File

- Design Specifications: Detailed drawings and dimensions of the part to be casted.

- Material Requirements: Information about the type of material to be used, such as aluminum, steel, or bronze.

- Tolerance Levels: Allowable variations in dimensions to ensure the part meets quality standards.

- Surface Finish Details: Specifications for the desired texture and appearance of the final product.

- Process Instructions: Guidelines for the casting process, including mold-making and finishing steps.

Importance of Casting Files in Manufacturing

Casting files play a pivotal role in ensuring the success of manufacturing operations. They provide a clear and standardized way to communicate design intent, production requirements, and quality expectations. Without casting files, manufacturers would face significant challenges in producing consistent, high-quality parts.

Benefits of Using Casting Files

- Improved Precision: Casting files eliminate guesswork by providing exact specifications for every aspect of the part.

- Enhanced Efficiency: By streamlining communication between designers and manufacturers, casting files reduce production time and costs.

- Quality Assurance: Casting files ensure that parts meet industry standards and customer expectations, reducing the risk of defects.

- Scalability: Whether you’re producing a single prototype or thousands of units, casting files enable consistent results.

Types of Casting Files

There are several types of casting files, each tailored to specific manufacturing processes and requirements. Understanding the differences between these files can help you choose the right one for your project.

1. 2D Drawing Files

2D drawing files are the most basic type of casting file. They include flat, two-dimensional representations of the part, complete with dimensions and annotations. While they lack the depth and detail of 3D models, 2D files are still widely used in traditional manufacturing settings.

2. 3D CAD Files

3D CAD files are digital models that provide a three-dimensional representation of the part. These files are highly detailed and allow manufacturers to visualize the part from all angles. 3D CAD files are commonly used in modern manufacturing due to their precision and versatility.

Read also:Margot Robbie A Comprehensive Look At The Life And Career Of A Hollywood Star

3. STL Files

STL files are a specific type of 3D file format used primarily in additive manufacturing and 3D printing. They represent the surface geometry of the part and are often used for creating prototypes or molds.

4. STEP Files

STEP files are a universal file format used for exchanging 3D data between different CAD software programs. They are widely used in industries that require high levels of interoperability and precision.

How Casting Files are Created

Creating a casting file involves several steps, from initial design to final validation. The process typically begins with a concept or idea, which is then translated into a digital model using specialized software.

Step 1: Conceptualization

The first step in creating a casting file is to conceptualize the part. This involves sketching out ideas, determining functional requirements, and identifying material and process constraints.

Step 2: Designing in CAD Software

Once the concept is finalized, the next step is to create a digital model using CAD software. This software allows designers to create detailed 2D and 3D representations of the part, complete with dimensions and annotations.

Step 3: Validation and Testing

Before the casting file is finalized, it must undergo rigorous validation and testing. This ensures that the design meets all functional and quality requirements. Simulation tools are often used to test the design under various conditions.

Software for Creating and Managing Casting Files

Several software programs are available for creating and managing casting files. These tools vary in terms of features, complexity, and cost, but all aim to streamline the design and production process.

Popular CAD Software

- AutoCAD: A widely used CAD program for creating 2D and 3D designs.

- SolidWorks: Known for its powerful 3D modeling capabilities and user-friendly interface.

- Fusion 360: A cloud-based CAD tool that offers collaboration features and advanced simulation tools.

- Creo: A robust CAD software used in industries like aerospace and automotive.

Simulation and Testing Tools

In addition to CAD software, manufacturers often use simulation tools to test casting files under real-world conditions. These tools help identify potential issues and optimize the design for better performance.

Applications of Casting Files in Various Industries

Casting files are used in a wide range of industries, each with its own unique requirements and challenges. Below are some examples of how casting files are applied in different sectors.

1. Automotive Industry

In the automotive industry, casting files are used to produce engine components, chassis parts, and other critical components. These files ensure that parts meet strict safety and performance standards.

2. Aerospace Industry

The aerospace industry relies heavily on casting files to produce lightweight, high-strength components for aircraft and spacecraft. Precision and reliability are paramount in this sector.

3. Medical Devices

Casting files are also used in the production of medical devices, such as implants and surgical instruments. These files ensure that devices meet stringent quality and safety requirements.

Best Practices for Using Casting Files

To get the most out of casting files, it’s important to follow best practices that ensure accuracy, efficiency, and quality. Below are some tips for using casting files effectively.

1. Collaborate with Experts

Work closely with designers, engineers, and manufacturers to ensure that the casting file accurately reflects the desired specifications and requirements.

2. Use Standardized Formats

Always use standardized file formats, such as STEP or STL, to ensure compatibility and interoperability across different software platforms.

3. Perform Regular Updates

Keep your casting files up to date with the latest design changes and improvements. This helps prevent errors and ensures consistency in production.

Common Challenges in Using Casting Files

While casting files offer numerous benefits, they also come with their own set of challenges. Below are some common issues that manufacturers may encounter when using casting files.

1. File Compatibility

One of the biggest challenges is ensuring compatibility between different CAD software programs. Using standardized formats can help mitigate this issue.

2. Data Loss

Data loss can occur during file transfers or conversions, leading to inaccuracies in the final product. Always back up your files and verify their integrity after transfers.

3. Complexity

Casting files can be complex, especially for intricate parts. Investing in training and advanced software can help overcome this challenge.

Future Trends in Casting File Technology

The future of casting files is bright, with advancements in technology paving the way for even greater precision and efficiency. Below are some trends to watch out for in the coming years.

1. AI and Machine Learning

AI and machine learning are being integrated into CAD software to automate design processes and optimize casting files for better performance.

2. Cloud-Based Collaboration

Cloud-based platforms are making it easier for teams to collaborate on casting files in real time, regardless of location.

3. Additive Manufacturing

As 3D printing technology continues to evolve, casting files will play an increasingly important role in additive manufacturing processes.

Conclusion

Casting files are an indispensable tool in modern manufacturing, offering unparalleled precision, efficiency, and quality. By understanding their importance, applications, and best practices, you can leverage casting files to enhance your production capabilities and achieve better results.

We hope this guide has provided you with valuable insights into the world of casting files. If you have any questions or would like to share your experiences, feel free to leave a comment below. Don’t forget to share this article with others who might find it useful, and explore more resources on our site to deepen your knowledge. Thank you for reading, and happy manufacturing!

How Tall Is Julian Works? Unveiling The Height Of The Rising Star

Baltimore Medical Examiner: A Comprehensive Guide To Forensic Investigations And Public Health

MostlyLucas: The Ultimate Guide To Understanding The Popular Content Creator

Cast Iron File Handles Michael Parrish Blog

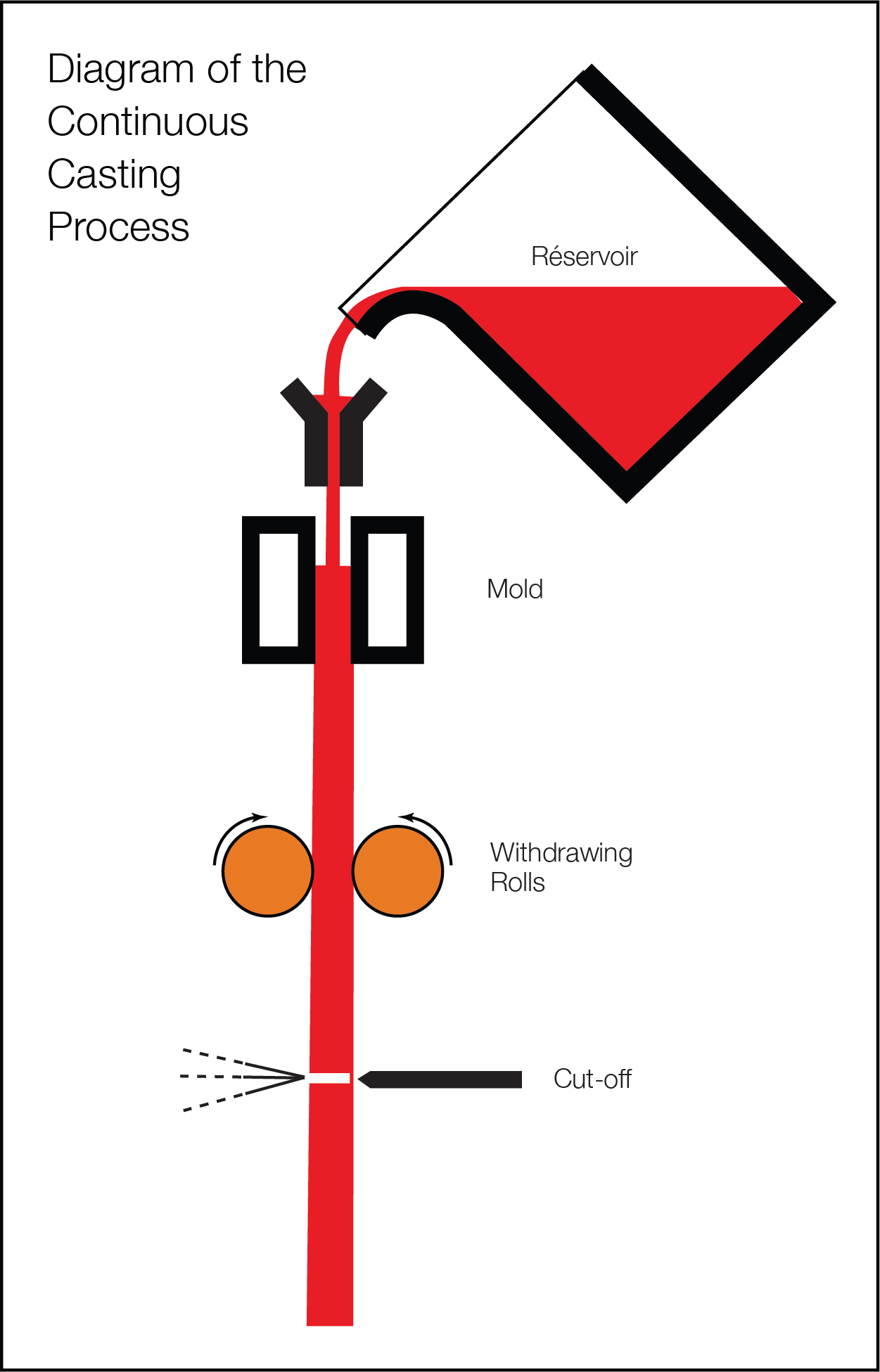

Continuous Casting Monmet