JSMES Taylor: A Comprehensive Guide To Understanding And Implementing The Framework

JSMES Taylor is a revolutionary framework designed to streamline manufacturing and production processes. It integrates cutting-edge technology with traditional methodologies to enhance efficiency, reduce costs, and improve overall productivity. In today’s competitive industrial landscape, understanding and implementing frameworks like JSMES Taylor is crucial for businesses aiming to stay ahead. This article dives deep into the intricacies of JSMES Taylor, providing you with a comprehensive guide to its principles, applications, and benefits.

As industries evolve, the need for robust systems to manage complex operations becomes more apparent. JSMES Taylor stands out as a solution that not only addresses current challenges but also anticipates future needs. From optimizing workflows to ensuring compliance with industry standards, this framework has become a cornerstone for many organizations. In this article, we will explore its origins, core features, and practical applications, supported by real-world examples and expert insights.

Whether you're a business owner, a production manager, or simply someone interested in industrial innovation, this guide is tailored to provide valuable insights. By the end of this article, you will have a clear understanding of how JSMES Taylor can transform your operations and contribute to long-term success. Let’s embark on this journey to uncover the potential of JSMES Taylor and how it can revolutionize your business.

Read also:Tonya Harding The Untold Story Of A Skating Legend

Table of Contents

- Introduction to JSMES Taylor

- History and Development of JSMES Taylor

- Core Principles of JSMES Taylor

- Key Features of JSMES Taylor

- Implementation Strategies for JSMES Taylor

- Benefits and Advantages of JSMES Taylor

- Real-World Applications of JSMES Taylor

- Challenges and Solutions in JSMES Taylor

- Future Trends in JSMES Taylor

- Conclusion

Introduction to JSMES Taylor

JSMES Taylor, or Just-in-Time Manufacturing Execution System Taylor, is a framework designed to optimize manufacturing processes. It combines advanced software solutions with lean manufacturing principles to ensure seamless operations. The primary goal of JSMES Taylor is to minimize waste, reduce lead times, and improve product quality. By leveraging real-time data and analytics, businesses can make informed decisions and respond quickly to changing market demands.

One of the standout features of JSMES Taylor is its ability to integrate with existing systems. Whether you're using ERP software or IoT devices, JSMES Taylor can seamlessly connect to these platforms, providing a unified view of your operations. This integration capability ensures that businesses can adopt the framework without overhauling their current infrastructure, making it a cost-effective solution.

History and Development of JSMES Taylor

The origins of JSMES Taylor can be traced back to the early 2000s when manufacturing industries began adopting digital technologies. Initially developed as a tool to enhance production efficiency, JSMES Taylor has evolved into a comprehensive framework that addresses various aspects of manufacturing. Over the years, it has been refined and expanded to meet the growing demands of modern industries.

The development of JSMES Taylor was heavily influenced by lean manufacturing principles, which emphasize waste reduction and continuous improvement. These principles were first introduced by pioneers like Henry Ford and later refined by Toyota in the form of the Toyota Production System. JSMES Taylor builds on these foundations, incorporating advanced technologies such as artificial intelligence and machine learning to further enhance its capabilities.

Key Milestones in JSMES Taylor's Development

- 2005: Initial development of JSMES Taylor as a production optimization tool.

- 2010: Integration of real-time data analytics to improve decision-making.

- 2015: Expansion to include IoT and cloud-based solutions.

- 2020: Adoption of AI and machine learning for predictive maintenance and process optimization.

Core Principles of JSMES Taylor

JSMES Taylor is built on several core principles that guide its implementation and operation. These principles ensure that the framework delivers consistent results and aligns with the goals of modern manufacturing. Below are the key principles that define JSMES Taylor:

1. Lean Manufacturing

Lean manufacturing is at the heart of JSMES Taylor. This principle focuses on eliminating waste in all forms, including overproduction, excess inventory, and unnecessary processes. By streamlining operations, businesses can reduce costs and improve efficiency.

Read also:Is Chief Keef On The Spectrum Exploring The Speculation And Facts

2. Real-Time Data Analytics

JSMES Taylor leverages real-time data analytics to provide actionable insights. This allows businesses to monitor their operations continuously and make data-driven decisions. Real-time analytics also enable predictive maintenance, reducing downtime and improving equipment lifespan.

3. Continuous Improvement

Continuous improvement, or Kaizen, is another core principle of JSMES Taylor. This approach encourages businesses to constantly evaluate and refine their processes to achieve better results. By fostering a culture of innovation, organizations can stay competitive in a rapidly changing market.

Key Features of JSMES Taylor

JSMES Taylor offers a wide range of features that make it a versatile and powerful tool for modern manufacturing. These features are designed to address the unique challenges faced by businesses in various industries. Below are some of the standout features of JSMES Taylor:

1. Production Scheduling

One of the key features of JSMES Taylor is its advanced production scheduling capabilities. The framework allows businesses to create optimized schedules that maximize resource utilization and minimize downtime. This ensures that production targets are met consistently.

2. Quality Control

JSMES Taylor includes robust quality control mechanisms to ensure that products meet the highest standards. By integrating with inspection systems, the framework can detect defects early in the production process, reducing waste and improving customer satisfaction.

3. Inventory Management

Efficient inventory management is crucial for minimizing costs and ensuring smooth operations. JSMES Taylor provides real-time visibility into inventory levels, allowing businesses to optimize stock levels and avoid overproduction.

Implementation Strategies for JSMES Taylor

Implementing JSMES Taylor requires careful planning and execution. Below are some strategies to ensure a successful implementation:

1. Conduct a Needs Assessment

Before implementing JSMES Taylor, businesses should conduct a thorough needs assessment to identify areas for improvement. This will help tailor the framework to meet specific requirements and ensure maximum ROI.

2. Train Employees

Employee training is essential for the successful adoption of JSMES Taylor. Businesses should provide comprehensive training programs to ensure that staff members are familiar with the framework and its features.

3. Monitor and Evaluate

Continuous monitoring and evaluation are crucial for identifying areas of improvement and ensuring that the framework delivers the desired results. Regular audits and performance reviews can help businesses stay on track.

Benefits and Advantages of JSMES Taylor

JSMES Taylor offers numerous benefits that make it an attractive solution for businesses in various industries. Below are some of the key advantages:

1. Increased Efficiency

By streamlining operations and reducing waste, JSMES Taylor helps businesses achieve higher levels of efficiency. This translates to lower costs and improved profitability.

2. Enhanced Quality

The quality control mechanisms in JSMES Taylor ensure that products meet the highest standards, leading to increased customer satisfaction and loyalty.

3. Scalability

JSMES Taylor is highly scalable, making it suitable for businesses of all sizes. Whether you're a small startup or a large enterprise, the framework can be tailored to meet your needs.

Real-World Applications of JSMES Taylor

JSMES Taylor has been successfully implemented in various industries, including automotive, electronics, and pharmaceuticals. Below are some real-world examples:

1. Automotive Industry

In the automotive industry, JSMES Taylor has been used to optimize production lines and reduce lead times. This has resulted in significant cost savings and improved product quality.

2. Electronics Manufacturing

Electronics manufacturers have leveraged JSMES Taylor to enhance their supply chain operations and improve inventory management. This has led to reduced costs and increased efficiency.

Challenges and Solutions in JSMES Taylor

While JSMES Taylor offers numerous benefits, businesses may face challenges during implementation. Below are some common challenges and their solutions:

1. Resistance to Change

Employees may resist adopting new systems. To overcome this, businesses should focus on communication and training to ensure a smooth transition.

2. Integration Issues

Integrating JSMES Taylor with existing systems can be challenging. Businesses should work with experienced vendors to ensure seamless integration.

Future Trends in JSMES Taylor

The future of JSMES Taylor looks promising, with several trends shaping its development. These include the increased use of AI, IoT, and cloud-based solutions. Businesses that embrace these trends will be well-positioned to thrive in the future.

Conclusion

JSMES Taylor is a powerful framework that can transform manufacturing operations. By leveraging its core principles and features, businesses can achieve higher levels of efficiency, quality, and scalability. Whether you're in the automotive, electronics, or pharmaceutical industry, JSMES Taylor offers solutions tailored to your needs.

We hope this guide has provided valuable insights into JSMES Taylor and its potential to revolutionize your operations. If you found this article helpful, feel free to leave a comment or share it with others. For more information on industrial innovation, explore our other articles on cutting-edge technologies and frameworks.

Simon Cowell: The Man Behind The Music And Talent Shows

Why Did Kim Greist Retire? Unveiling The Truth Behind Her Decision

Puzzle Tips: Mastering The Art Of Problem-Solving And Fun

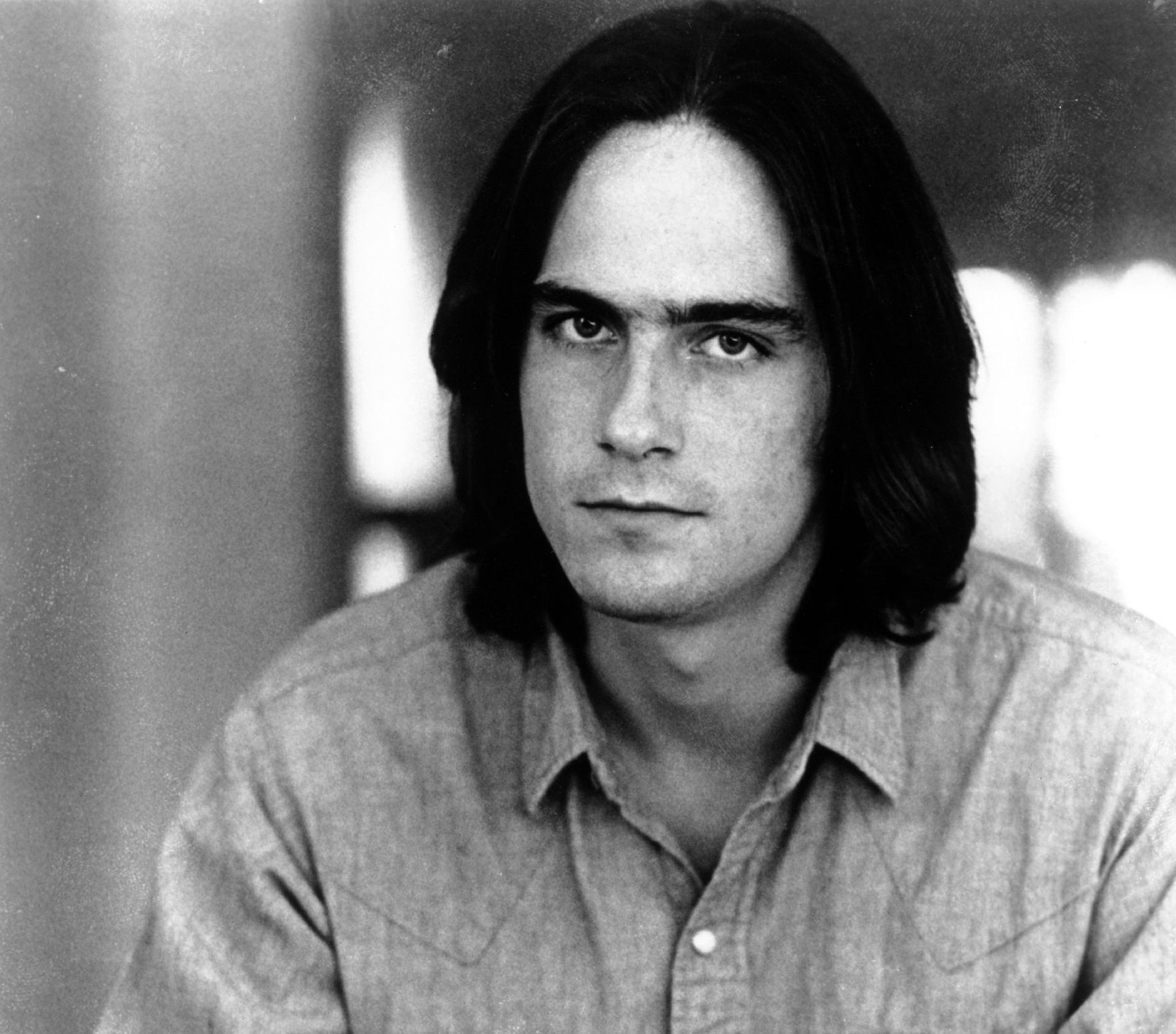

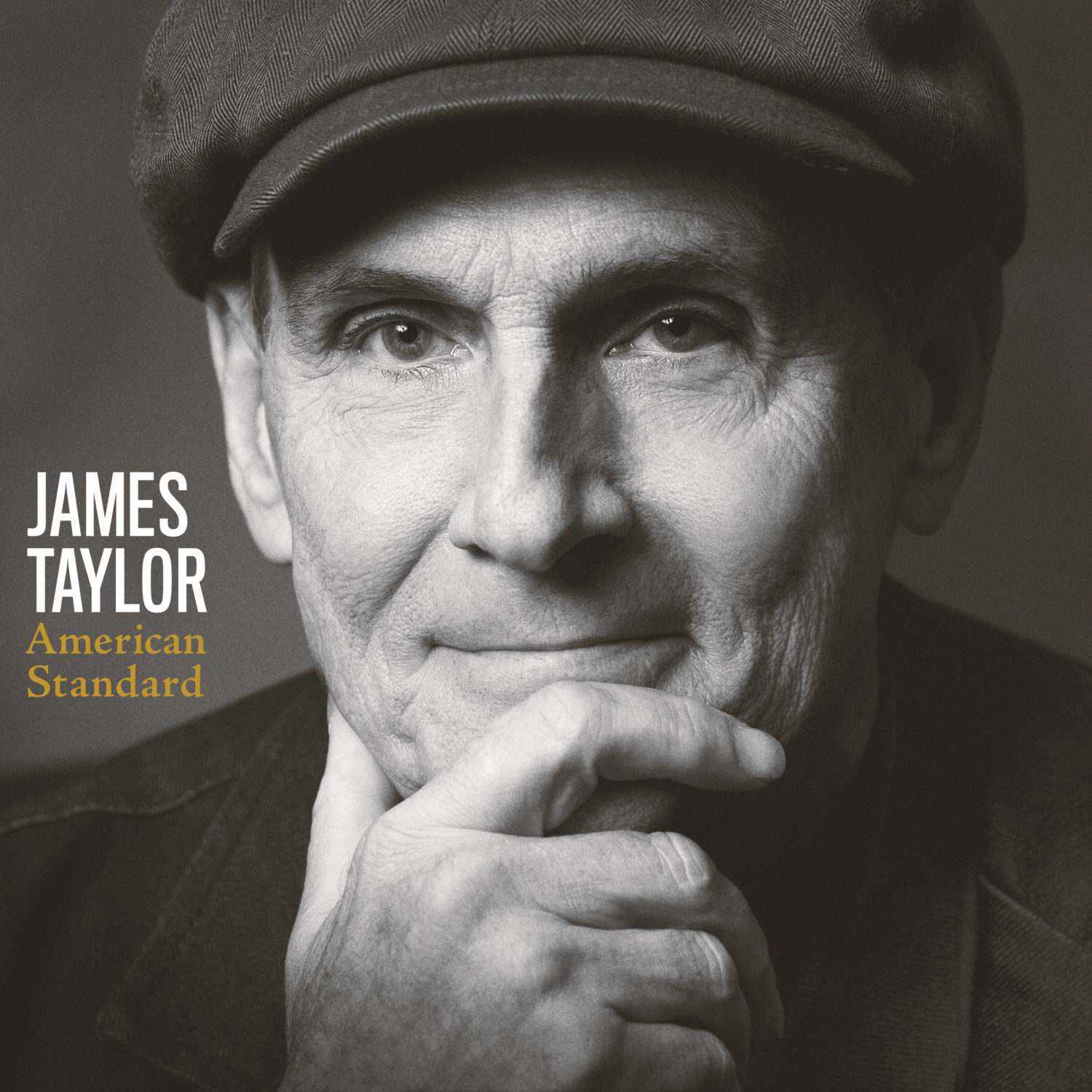

James Taylor North Carolina Music Hall Of Fame

LEGENDARY SINGERSONGWRITER JAMES TAYLOR TO RELEASE NEW ALBUM AMERICAN